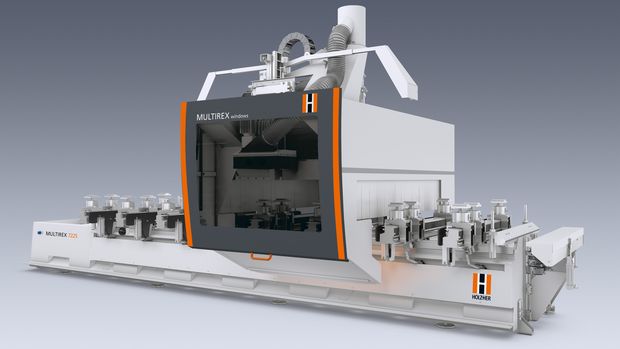

The new HOLZHER 5-Axis CNC machine for machining windows, doors and staircases

04/17/2015Constructed for the most highly demanding work, the solid and well-thought-out construction of these machines represents the latest in modern and application-friendly industrial design. The high quality equipment packages on all MULTIREX CNC machines are perfectly matched to the user groups and a number of practical options allow even greater adaptation to the specific application. There are however certain differences between the two 5-axis centers particularly in terms of machining dimensions. The console table of the MULTIREX 7125 offers machining lengths in the X-axis up to 5,440 mm and is available in the MULTIREX 7225 model even for lengths up to 7,220 mm. In this way, machining of longer components for staircases and conservatories, etc. is enabled without any problem. Even large door components can be machined in a highly efficient and trouble-free manner in pendular operation. With 1,400 mm or 1,600 mm in the Y-axis as well as a Z-stroke of 565 mm, both of these machining centers are perfectly equipped for individual and highly variable machining operations.

Two, automatically positioning table versions are offered for the MULTIRREX 7125 Automatic and MULTIREX 7225 Automatic. Here the X-Move table offers automatic console positioning as a standard feature. The VarioDrive table is a completely new development available as an upgrade for the Automatic models for moving the suction cups or frame clamps and consoles under servo-control for extremely precise positioning. During this operation all axes are move synchronously thus limiting conversion times to an absolute minimum. The MULTIREX 7125 can perfectly process workpieces up to 210 mm in height from the top of the suction cups, whilst the larger MULTIREX 7225 can handle even bigger workpieces of 300 mm in height. The solidly-built console tables used on the automatic series are equipped as standard with 8 consoles and 6 charging aids.

The top model in the series is the MULTIREX 7225 Windows, which is already equipped with the VarioDrive machine table as a standard feature. The controlled suction cup carriages with quick-change bayonet lock also serve for mounting the frame clamps and run in two extremely stable, high precision linear guides per console. The high positioning accuracy of the automatic frame clamps is laid out perfectly for automatic reclamping of rod profiles and curves. The Windows models also include standard features such as the extremely powerful 17 kW spindle with PRO-Torque technology, a software-controlled "interlock" for the C and A axes with advantages particularly when performing milling operations with maximum chip removal.

Mechanically the MULTIREX 5-axis machining centers are distinguished particularly by the extremely dynamic action of the 5-axis head and smooth motion sequences with interpolating movement.